.gif)

|

NINGBO TAEPO Communications Co., Ltd.

|

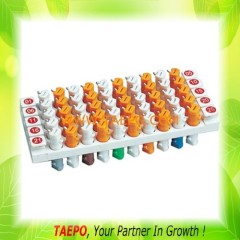

25 pairs gel filled straight splicing module

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

It is used throughout the distribution level, in the mechanical or heat shrink copper enclosure. I

25 pairs gel filled straight splicing module

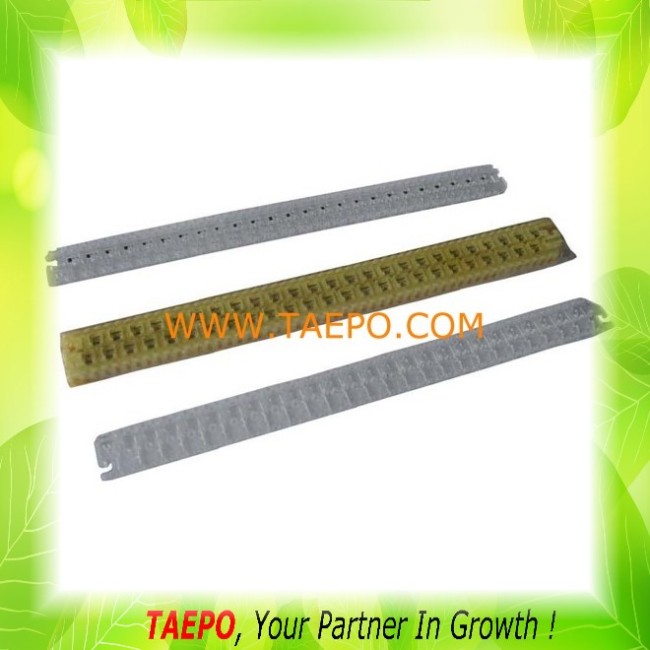

| ITEM NO | UNIT | DESCRIPTIONS |

| TP-1307-10 | pcs | 10 pairs straight splicing module, dry |

| TP-1307-10G | pcs | 10 pairs straight splicing module, gel filled |

| TP-1307-20 | pcs | 20 pairs straight splicing module, dry |

| TP-1307-20G | pcs | 20 pairs straight splicing module, gel filled |

| TP-1307-25 | pcs | 25 pairs straight splicing module, dry |

| TP-1307-25G | pcs | 25 pairs straight splicing module, gel filled |

| TP-1307-2TS | pcs | 2-pole test cord for splicing module, test plug to screw terminal |

Descriptions

TP-1307-25G 25 pairs straight splicing module is used throughout the distribution level, in the mechanical or heat shrink copper enclosure. It is highly reliable and cost-effective wire connection system for modern telecommunications and data networks.

It adopts IDC (Insulation Displacement Connection) technique, which means that no soldering, wire-stripping or the use of screws is necessary , thus dramatically reducing the risk of a poor termination and increasing the wiring productivity.

Main Features

Insulation Displacement Connection

No Wire-stripping, screw and solder free

Reliable connections

Flame retardant performance

Modular design and installations

Gas tight connection

One push wire insertion

No Wire-stripping, screw and solder free

Only one inexpensive tool required

Technical Descriptions

Working temperature: -40℃ ~ 80℃

Relative humidity: ≤93%(+40℃)

Appearance: the color of all metal and plastic parts is uniform, without any scratch, rust, crusting and cracks.

The labels are clear and complete.

Insulation resistance: under normal ambient conditions, after high temperature test, low temperature test, temperature varing test and humidity heat test, the insulation resistance between any two independent contacts, and/or between contacts and metal parts ≥ 1000MΩ

Contact resistance between contacts: under normal ambient conditions, the contact resistance between contacts ≤7 mΩ. After high temperature test, low temperature test, temperature varing test and humidity heat test, the increasing resistance ≤3 mΩ And after inserting the connection cord (or test cord) into the module for 200 times, the increasing resistance ≤3 mΩ

Contact resistance between conductor and contact: under normal ambient conditions, the contact resistance between contacts ≤3 mΩ. After high temperature test, low temperature test, temperature varing test and humidity heat test, the increasing resistance ≤2 mΩ. And after terminating for 200 times, the increasing resistance ≤2 mΩ.

Dielectric strength: under normal ambient conditions, after high temperature test, low temperature test, temperature varing test and humidity heat test, the insulation resistance between any two independent contacts, and/or between contacts and metal parts is able to withstand an AC voltage of 1000V (virtual value) at 45Hz~60Hz sinowave for 1 minute, without spark over and flying arc

Gas tight performance: contact touches the conductor at both sides, and thus forming the gas tight area, while the area of gas tight occupies ≥50% of the touched area on each side.

Conductor diameter range: 0.32mm-0.6mm, while insulation ≤ 1.4mm

Pulling strength:≥25N while pulling from the vertical side of the contacts

Flame retardant performance: all plastic parts are flame retardant, reaching grade of UL FV0

Life circle: ≥200 times

Order Data

Item No | Descriptions |

TP-1307-25G | 25 pairs straight splicing module, gel filled |

Related product for 25 pairs gel filled straight splicing module

Related product for 25 pairs gel filled straight splicing module